Custom Metal Parts

FollowOverview

-

Founded Date 15 March 1998

-

Sectors BPO

-

Posted Jobs 0

-

Viewed 6

Company Description

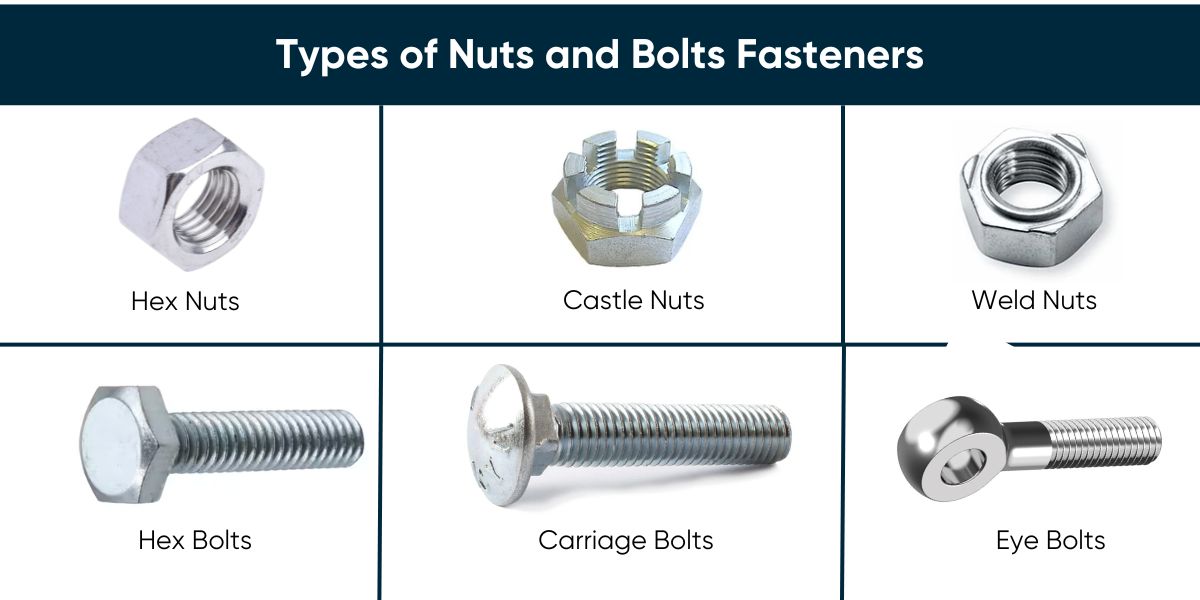

Top 10 Benefits of Using Custom Metal Parts for Your Projects

Whether you’re fabricating precision machinery or constructing structural components, bespoke metal parts offer you unmatched advantages. When seeking high-quality manufacturing solutions, many engineers turn to your go-to metal parts manufacturer to achieve optimal results in their projects. You’ll find that while standardized parts provide simplicity, custom metal components deliver exactness and innovation. Through precise specifications, you’re gaining both durability and design freedom, reshaping basic manufacturing processes into customized solutions that perfectly align with your engineering requirements and quality standard

Your machine lifespan depends on maintenance schedules, but you’ll typically get 15-20 years from well-maintained equipment. Most manufacturers recommend consulting your go-to metal parts manufacturer for optimal maintenance timing, with regular inspections and parts replacement occurring every 3-6 months during operatio

You’ll find metal parts manufacturing combines state-of-the-art precision engineering with sophisticated quality control at every step. Modern facilities employ digital twin technology, robotics, and CNC machining to achieve tolerances as precise as ±0.0001 inches. Advanced surface finishing and metallurgical testing guarantee components meet exact specifications in controlled environments. From your smartphone to aerospace components, this technical expertise shapes the products you rely on daily. The innovations behind these processes reveal an even more fascinating stor

What’s often overlooked is the role of digital twin technology in modern manufacturing. Before cutting any metal, engineers create detailed virtual simulations of both the manufacturing process and the finished component. This allows you to identify potential issues in tooling paths, stress points, or design flaws before investing in physical production. The technology reduces waste, maximizes material usage, and guarantees first-article success rates well above industry standard

Before purchasing metal parts, you’ll need to evaluate five essential factors that determine success: material selection, quality control certification, specifications and tolerances, manufacturing methods, and supplier communication. Each element directly impacts your product’s performance, safety, and total cost of ownership. Careful consideration of material composition, manufacturing processes, and quality standards will help prevent costly mistakes. The following observations will equip you with essential knowledge for making informed decision

Quality control measures shouldn’t be compromised when seeking affordable solutions. Look for fabricators who maintain ISO certifications and employ rigorous testing protocols. These standards guarantee your parts meet industry specifications and safety requirements, potentially saving you money by preventing costly failures or replacements down the lin

Precision engineering drives modern metal parts manufacturing, encompassing a range of specialized processes to convert raw materials into finished components. The industry’s stringent quality control measures guarantee that each part meets exact specifications through multiple inspection points during production. Advanced production techniques, including computer numerical control (CNC) machining, electrical discharge machining (EDM), and precision grinding, allow for tolerances as tight as ±0.0001 inches in some applications. You’ll find these exacting standards particularly essential in aerospace, medical devices, and automotive sector

You’ll want to verify ISO 9001 certification for quality assurance. When selecting a manufacturer, make sure to check if they have your go-to metal parts manufacturer since these credentials demonstrate their commitment to excellence. Additionally, look for industry-specific standards like AS9100 for aerospace or ISO/TS 16949 for automotive manufacturing and rigorous materials testing protocol

Custom metal parts provide superior performance characteristics customized to your specific application. You can select from a wide range of metals and alloys, each offering distinct properties such as corrosion resistance, thermal conductivity, or mechanical strength. This customization extends to surface treatments and finishing options, allowing you to enhance the durability and functionality of your components. The ability to optimize these characteristics results in parts that perform better and last longer in their intended application

You can’t fully automate metal parts manufacturing without human oversight due to critical automation challenges, quality control requirements, and safety protocols that demand skilled operator supervision throughout production processe

The complexity of metal manufacturing processes, combined with stringent industry standards and safety requirements, makes human supervision an essential component that cannot be fully eliminated through automatio

The environmental impact of metal manufacturing has led to innovative recycling and waste reduction strategies. You’ll find that modern facilities implement closed-loop coolant systems, metal chip recovery programs, and energy-efficient machinery to minimize their ecological footprint. Advanced planning software enhances material utilization, reducing scrap rates to sometimes less than 5% of raw material inpu

The environmental impact of metal manufacturing has led to innovative recycling and waste reduction strategies. You’ll find that modern facilities implement closed-loop coolant systems, metal chip recovery programs, and energy-efficient machinery to minimize their ecological footprint. Advanced planning software enhances material utilization, reducing scrap rates to sometimes less than 5% of raw material inpu